StretchWrappers - Doverco

LogoControl

How can an automatic pallet wrapper improve your productivity compared with hand wrapping?

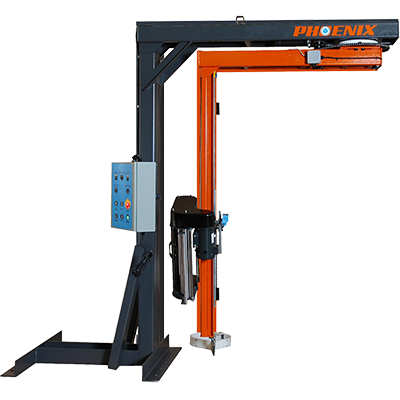

What kind of stretch wrapper are you looking for?

Our Logix and Phoenix stretch wrappers offer several advantages over hand wrapping when it comes to improving productivity. Here are some ways an automatic pallet wrapper can enhance efficiency:

- Film Savings: Automatic pallet wrappers often include advanced features like pre-stretch systems that stretch the film before applying it to the pallet. This helps optimize film usage and reduce film consumption, resulting in cost savings over manual wrapping methods.

- Load Security and Stability: Automatic pallet wrappers utilize advanced wrapping techniques and technology to achieve consistent, tight, and secure wraps. This ensures that the load remains stable during handling, transportation, and storage, minimizing the risk of damage and reducing product loss or wastage.

- Consistency and Quality: Automatic pallet wrappers ensure consistent and uniform wrapping of pallets. They are equipped with precise controls and settings that maintain consistent tension, film application, and wrap patterns. This results in a secure and professional-looking wrap every time, reducing the risk of load shifting or damage during transit.

- Ergonomics and Safety: Hand-wrapping pallets can strain the back, shoulders, and wrists of workers, leading to potential injuries and discomfort. Automatic pallet wrappers eliminate the need for repetitive manual labor, reducing the risk of musculoskeletal issues and workplace injuries. This promotes a safer and healthier work environment for employees.

- Speed: One of the key benefits of an automatic pallet wrapper is its ability to wrap pallets at a significantly faster rate compared to manual wrapping. The machine can wrap pallets consistently and swiftly, saving valuable time and increasing overall productivity. It eliminates the need for manual labor-intensive wrapping, allowing employees to focus on other tasks.

- Reduced Labor Costs: Manual pallet wrapping requires dedicated personnel to perform the wrapping process, which can be time-consuming and physically demanding. By utilizing an automatic pallet wrapper, businesses can reduce labor costs by minimizing the number of workers required for this task. Employees can be assigned to more value-added activities, improving overall efficiency.

- Customization and Programming: Many automatic pallet wrappers come with programmable settings, allowing businesses to tailor the wrapping process to their specific requirements. They can adjust parameters such as wrap tension, film layers, and wrap patterns, ensuring optimal load stability and protection. This customization capability increases efficiency and reduces material waste.

By investing in an automatic pallet wrapper, businesses can streamline their wrapping operations, increase productivity, enhance load security, and improve overall efficiency compared to manual hand wrapping. It offers a range of benefits that contribute to a more cost-effective and productive packaging process.